COFFEE ROASTING

Roasting, as we will tell you, takes place in the same way at all levels, from the small tasting batch to the large production one. It is a complex job, which requires experience and desires to experiment: you work with a natural and variable product. It is important, therefore, to know that each new coffee will require a study of what is the best way to roast it to enhance all its qualities.

Before starting to roast, it is essential to remember that coffee is a product that arrives green here in the roastery. And, therefore, we have to analyse the beans, evaluate their characteristics and defects, in order to decide how to roast them.

Since sometime only small samples are available, before roasting them, it’s important to put down all of their physical attributes, such as screen size, moisture content, water activity, presence of defected beans, etc.

All these features greatly influence the roasting process: in fact, the roaster will have to work to ensure that every positive characteristic is exalted and every defect attenuated.

Roasting machines

From the first recorded roasting methods, thin pans made from metal or porcelain used in the 15th century, till today a lot has changed, different machines have been created and the technology has given an incredible boost.

Roasters have a very different capacity, from 50 grams to 600 kg per batch and can operate in either batch or continuous modes.

There is an incredible variety of roasting machines on the market, among which the main types are:

Drum roasters direct flame

Drum roaster irradiation heating

Drum roaster indirect heating

Tangential

Continuous roasting

Fluid bed

Obviously there are many different brands and there is not a perfect machine, but everyone has to choose according to his needs.

Heat is transferred to the beans mainly in three ways: through conduction, convection and irradiation. Each machine uses all three methods of heat transfer, but obviously the impact that each method would have on the beans will be quite different depending on the structure of the machine.

The roasting process

The roasting process is quite complex because many chemical changes help to completely modify the appearance and structure of the coffee. This process reveals the aroma and flavour that are kept inside the green coffee beans. Green coffee has about 350 aromatic compounds, roasted coffee about 850.

Each roaster then identifies what he/she wants to achieve and above all knows well his machine: the correct management of heat and air that act on the beans allows you to adapt the roasting curve to each coffee.

Properly roasted coffee does not smell like smoke, ash or too roasted and, above all, it is not dark to the eye. As all products that are processed with cooking, this must be carried out correctly and controlled, otherwise there is the risk of irreparably ruining an excellent raw material.

Roasting can enhance the best characteristics of a coffee, but also make its possible defects evident: a good roaster must be able to find a balance to work every batch at best.

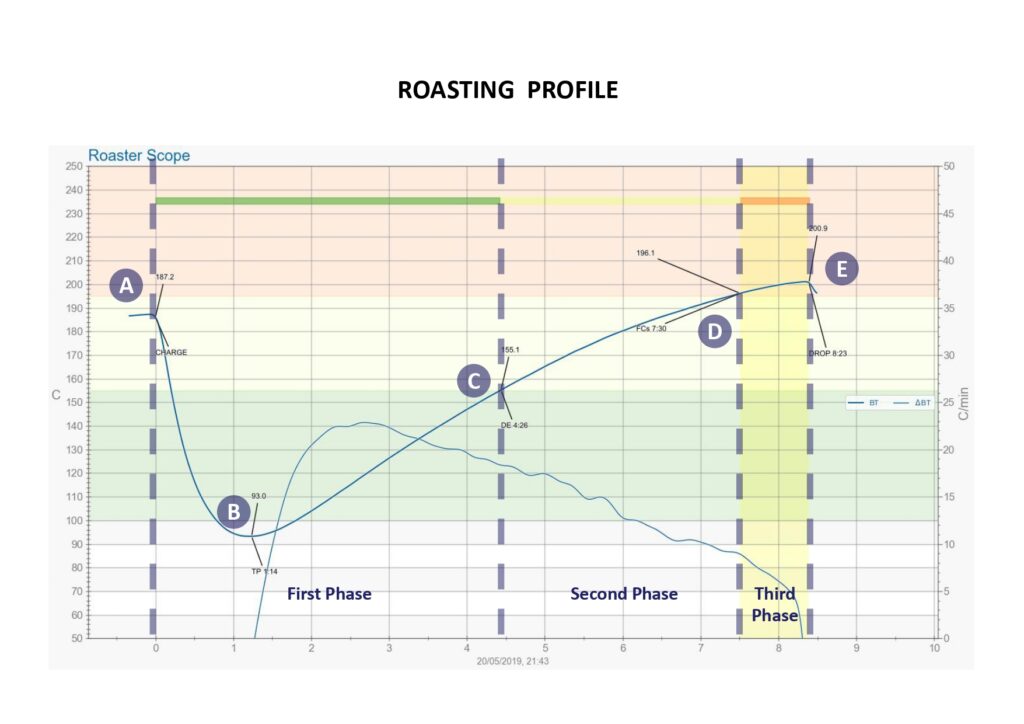

There is more than one stage in roasting: First phase (called also Drying), Second phase (also called Maillard), Third phase (called also Development) and Cooling. Thanks to specific software, connected to probes that control the temperature of both the beans and the air in the drum, the roasting curve can be monitored. This is outlined on a degree/time graph.

During drying stage (endothermic) coffee absorbs heat and start losing some moisture; there is a moment called “yellow point” when beans start changing colour from green to yellow and they lose more than 40% of their water content. Here the second phases start.

Now the beans begin to darken in what is called the Maillard reaction, which, among other chemical reactions, is responsible for browning: sugars and amino acids react creating numerous diverse aromas.

During the third phase, many of the features developed during the two previous moments are completed: it is essential to slow down the roasting process. This third phase is easily recognizable because the coffee starts to pop, due to the pressure of the steam: this is called the first crack. At this point, the reaction inside coffee changes and it becomes exothermic: while drying and browning, beans collect energy that makes the coffee “explode”.

Whether it is a filter or an espresso, whether it is a coffee for the home moka or roasted for a championship of roasters, what must never be missing is the care in roasting it.